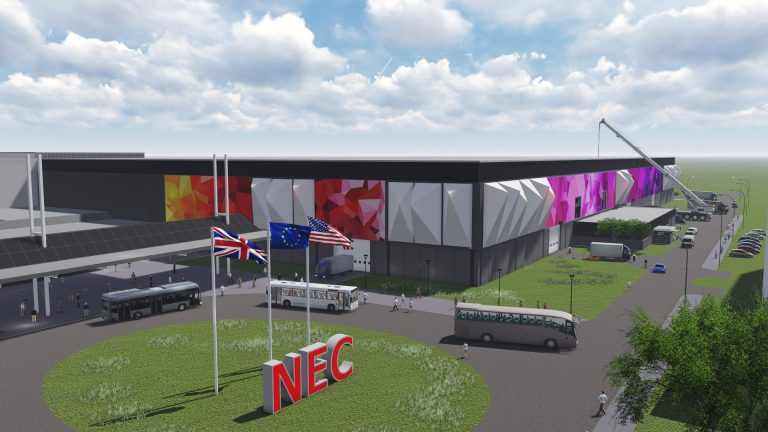

A building in the heart of Unity Campus, South Cambridge, is to be transformed into a new £20 million multi-let business space by architect firm NBBJ. The project is the first phase of Howard’s Group investment to create a new campus style business park in the area. The Works is NBBJ’s scheme that aims to provide 63,000 square feet of flexible, modern business space, incorporating the pre-cast concrete frame of the original building. The scheme is expected to be completed in late 2019. “The goal at The Works is to create an environment where dynamic, growing businesses can thrive. South Cambridge has a huge number of occupiers looking for something a little different to the institutional office stock available, that will help them to both recruit and retain talent and inspire and engage their workforce. With excellent train services, cycle routes into central Cambridge and easy access to the main road network, this is the perfect campus-style office location,” said William Jewson, Howard Group’s Development Director. “The Works is the first stage of our masterplan for Unity Campus. The ultimate aim is to create a new kind of business park, with striking architecture, grade A infrastructure, a pedestrian and cycle friendly circulation space and excellent amenities both internally and externally. We would love to talk to any businesses interested in making the move into something a little more exciting than the more conventional business park,” William added. NBBJ is a different kind of design practice, one that helps its clients drive innovation by creating highly productive, sustainable spaces that free people to live, learn, work and play as they were meant to. Founded in 1943, NBBJ has locations in Boston, Columbus, Hong Kong, London, Los Angeles, New York, Pune, San Francisco, Seattle and Shanghai. Its global network of “renaissance teams” includes more than 700 researchers, strategists, nurses, architects, anthropologists, planners and interior designers who generate ideas that have a profound and lasting impact.