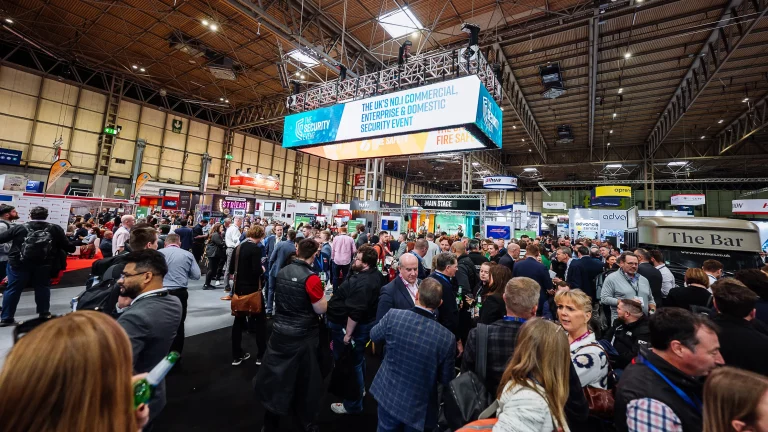

Abloy UK and HKC successfully showcased their market-leading digital access solutions and intelligent intruder alarm systems at The Security Event 2025, held at the NEC Birmingham. The three-day exhibition attracted thousands of security professionals from across the UK, Ireland, and beyond to explore the latest innovations in security and smart building management. With the growing convergence of physical security and digital technologies, the event provided an ideal platform for Abloy and HKC to demonstrate how their integrated systems support safer, smarter, and more sustainable buildings. Visitors to the stand engaged with live product demos, received expert insights, and explored how to adopt digital connected systems with confidence. Pip Courcoux, Technical and Product Director at Abloy UK, commented: “As buildings become smarter and the demand for seamless, secure movement increases, digital access is no longer a luxury – it’s essential. “Buildings are rapidly becoming digital environments, and access control plays a key role in enabling that transformation. From commercial offices to critical infrastructure, the need for flexible and scalable access management is growing rapidly. “We were delighted to connect with customers, consultants, and industry leaders at The Security Event 2025 to share how our solutions – including PROTEC2 CLIQ and PRIMO – can support their journey to smarter, more secure, and more sustainable operations.” Abloy UK’s portfolio on display included its comprehensive range of electromechanical and wireless locking systems, software platforms for access management, and cloud-based solutions that enable secure, real-time control of doors, cabinets, and gates – even in remote or high-risk environments. Damian Lloyd, Marketing Lead at HKC, echoed this, highlighting the rapid evolution of intruder detection systems in the digital age: “Over the past decade, the security landscape has undergone a major transformation – driven in large part by the evolution of intruder alarm connectivity. “Technological advancements have reshaped industry attitudes, prompting a shift in how alarm systems are designed, installed, and maintained. Modern alarm systems are now smarter, more integrated, and significantly more reliable than earlier generations. Innovations in wireless communication, cloud computing, artificial intelligence, and the Internet of Things (IoT) have all contributed to this progress. “These technologies have ushered in a new era, enabling real-time insights, effortless remote access, and a greatly enhanced user experience. The Security Event was the ideal opportunity for us to discuss this topic with visitors face-to-face, demonstrating how our HKC solutions can be tailored for residential, commercial, and vertical specific environments.” HKC’s stand featured its latest range of intruder alarm panels, wireless sensors, app-controlled systems, and cloud management tools – all designed with installers and end-users in mind. The company’s integrated approach aligns with today’s demand for security systems that not only detect but also deter and inform. Both Abloy UK and HKC are part of ASSA ABLOY, the global leader in access solutions, and their participation in The Security Event 2025 demonstrates the group’s commitment to innovation, collaboration, and future-ready technology. For more information on HKC Security, please visit: hkcsecurity.com For further information on Abloy UK, visit https://bit.ly/4hN2iOO, call 01902 364 500, or email info@abloy.co.uk Building, Design & Construction Magazine | The Choice of Industry Professionals