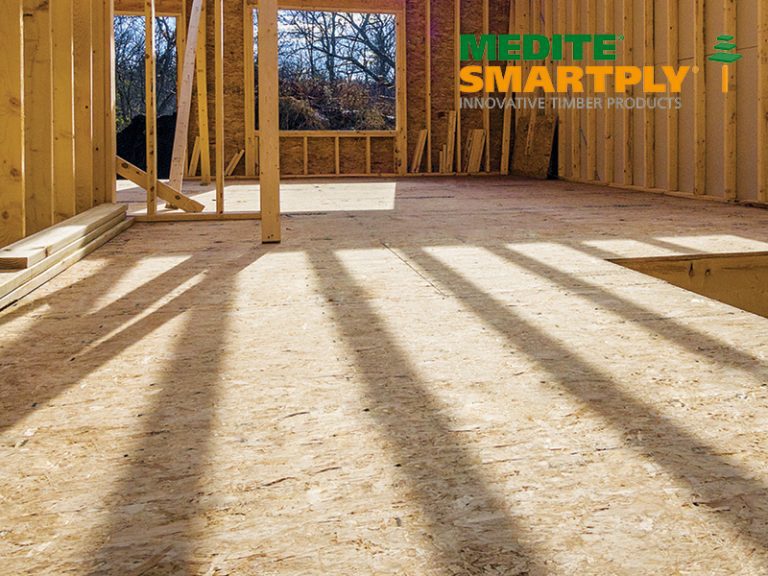

MEDITE SMARTPLY, the market-leading manufacturer of sustainable wood-based panels, has successfully completed extensive testing with a UKAS-accredited laboratory on flooring solutions featuring SMARTPLY MAX DB and SMARTPLY SURE STEP DB. The OSB panels used in timber flooring systems for internal residential floors have achieved the airborne sound insulation performance of 40dB as required by the Building Regulations in England, Wales, and Northern Ireland. Compared to the traditionally used chipboard solution, these flooring systems offer a host of benefits. Opting for SMARTPLY MAX DB enables a thinner, stronger and 30% lighter alternative. Opting for SMARTPLY SURE STEP DB provides an airtight, durable, and slip-resistant solution, ticking all the boxes for operational goals. Roly Ward, Head of Business Development at MEDITE SMARTPLY, commented: “Peace and quiet are essential for a comfortable and healthy home environment. We are excited to bring to the market new applications for our products that have been tested in flooring systems and offer sound reduction while providing the construction industry with a lighter, safer, airtight, and sustainable flooring solution as an excellent alternative to traditionally used materials.” MEDITE SMARTPLY has tested its new 18mm SMARTPLY MAX DB in flooring systems. The panel helps achieve 40dB, which is required for internal residential floors under the Building Regulations in England, Wales, and Northern Ireland. The panel also offers weight savings, allowing for easier handling on the construction site, as well as simpler transportation and reduced costs. SMARTPLY SURE STEP DB is an airtight, tongue-and-groove panel with a high-performance coating. Using it as an airtight layer for flooring or decking can contribute to sustainable building practices and reduce energy consumption for heating. This solution complies with building regulations and is certified as airtight. What’s more, SMARTPLY SURE STEP DB’s unique coating enhances durability during the construction phase and ensures slip resistance in all site conditions. SMARTPLY OSB panels are highly durable because of their manufacturing process. The cross-orientation of the wood strands is key; this alignment allows for greater surface coverage for the adhesive, resulting in the panel’s superior strength. SMARTPLY OSB is a sustainable material that can add value throughout the supply chain. Sourced from sustainably managed and accredited Irish forests, SMARTPLY wood-based panels not only store carbon during the growth of trees but also continue to lock it in throughout the manufacturing process and the entire lifespan of the product and the buildings in which they are used. SMARTPLY’s OSB panels are fully certified, UKCA and CE marked, legally sourced, and sustainable. Because OSB is made of wood strands, the whole tree is used, and nothing is wasted. The entire SMARTPLY OSB range has been manufactured using no added formaldehyde, contributing towards healthier environments for dwellers in England, Wales, and Northern Ireland. “SMARTPLY OSB has one of the lowest embodied carbon of any mainstream building material. This makes it ideal for building energy-efficient homes – offering a warmer home and a reduction in energy consumption – keeping us on track towards a net-zero future,” added Roly Ward. SMARTPLY MAX DB and SMARTPLY SURE STEP DB are engineered OSB wood-based panels that meet regulatory requirements and exceed expectations, making them a smarter choice for specifiers, housebuilders, contractors, and homeowners. Building, Design & Construction Magazine | The Choice of Industry Professionals