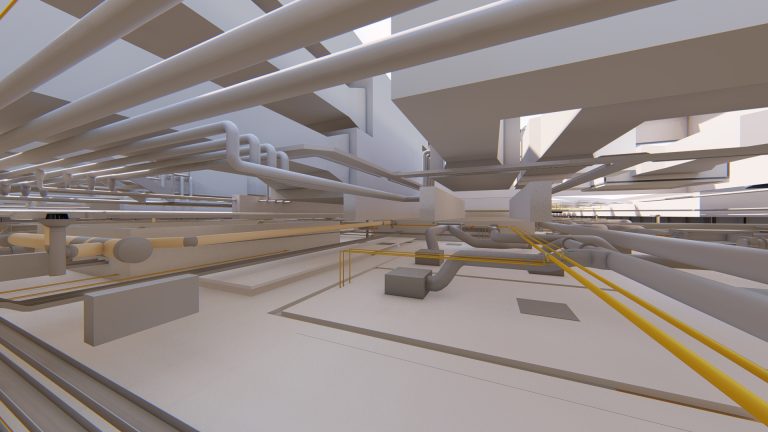

Winvic Wins IM Properties Contract Following Funding from Immediate Capital Group Winvic Construction Ltd, a leading main contractor that specialises in the design and delivery of multi-sector construction and civil engineering projects, has been awarded a contract by repeat client IM Properties to construct a 2.94 million sq ft global parts logistics centre at Mercia Park in Leicestershire. The five industrial units will be leased to Jaguar Land Rover, making this the UK’s largest single occupier logistics park. IM Properties recently announced that Intermediate Capital Group (IGC) would be forward funding the new campus – at the heart of the UK’s Golden Triangle – which will service 80 countries. Aiming for the scheme to be Net Zero in construction, Mercia Park provides a further step forward for IM Properties’ sustainability ambitions for future developments, complimenting an extensive social value programme and a skills and training initiative already underway at the scheme. Winvic’s investment in people, technologies and forward-thinking approaches to construction puts the main contractor in the ideal position to support IM Properties’ green commitments. Units 2 and 4 are the largest, at 1,000,000 sq ft, with 514m x 181m x 18m steel frames. Units 3 and 5 are each 300,000 sq ft and Unit 1 is 200,000 sq ft and all five buildings will comprise office space, totalling 107,000 sq ft. To date, unusual project challenges have included designing the link building slabs to withstand adjacent warehouse racking leg loads and ensuring the structural frame can tolerate enhanced loading in block stacking areas. The Winvic team started works on Monday, 15 February and the project will be handed over in September 2022. However, Winvic has been on site at the north-west Leicestershire logistics park site – close to Junction 11 of the M42 – since September 2020 for IM Properties, delivering a £21 million civils and infrastructure contract, including S278 works. The bulk earthwork excavations and bund creation works are now complete, planting of thousands of trees and shrubs has begun and the programme of highways works is progressing at pace. Winvic will undertake preparatory earthworks, before starting construction of the first three units to the south of the estate road, before commencing Units 4 and 5 to the north. In addition to the industrial facilities, Winvic will also be delivering associated works including the construction of five yards and car parks accommodating over 2,300 vehicles. Surface and foul water drainage installation, and external services will also be undertaken, including intricate underground connections between the completed infrastructure works and each individual unit. Additionally, the area to the north of Unit 3 presents a concentrated number of services that require complex clash detection and planning activities. Danny Nelson, Director and Head of Industrial at Winvic, commented: “We have been on an incredible journey with IM Properties to date, working on numerous projects, but schemes of this nature don’t come around too often and so Mercia Park is one we are very proud to be a part of. To be selected by IM Properties as the delivery partner on a project of this size, scale and importance is testament to the relationship that has been cultivated over many years and that we continue to be market leaders in the sector. Our investment in people, technologies and forward-thinking approaches to construction puts Winvic in the ideal position to support the green commitments made by IM Properties and we’re looking forward to constructing our largest industrial facility to date – at almost 3 million sq ft – for IMP and end user, UK automotive pioneer, Jaguar Land Rover.” Jason Jasper, UK project director for IM Properties, said: “This is not only the largest single occupier deal ever to be agreed and funded but a major planning, construction and project delivery accomplishment. We’ve taken a 238-acre site from zero to development ready in four years. Typically a scheme of this scale would be delivered in separate phases over a five-to-ten-year period. After years of investment and hard work, it will be exciting to see all six buildings come out of the ground at the same time. We have worked hard with Winvic and our supply chain to manage the logistical challenges that comes with building this volume at the same time together with managing a phased handover of the development to JLR.” Winvic is working closely with IM Properties and its supply chain to explore job and training opportunities. The Mercia Park Employment Scheme and local Employment and Skills Partnership represents a pledge to ensure local job seekers, students and businesses can benefit from the construction of the 238-acre industrial park. Six local authority areas, which surround the Leicestershire site, are being targeted during construction and people looking for an opportunity who live locally to Mercia Park can get in touch with IM Properties or Winvic. Winvic was also engaged in November by DSV to design, construct and partially fit out its new facility at Mercia Park, which comprises a warehouse, cross-dock terminal and three-storey office building. For more information on Winvic, the company’s latest project news and job vacancies please visit www.winvic.co.uk. Join Winvic on social media – visit Twitter @WinvicLtd – and LinkedIn.