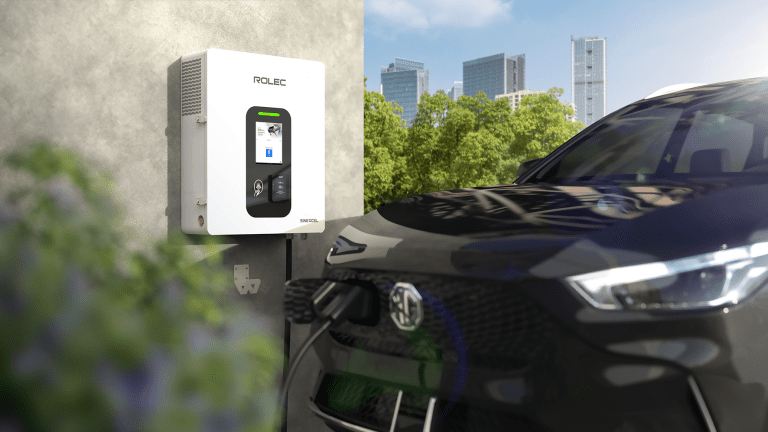

Rolec and Sinexcel partnered in 2022, to deliver high-quality, scalable, and reliable DC charging products, dedicated to operational excellence, accessibility, and innovation. The partnership has set the standard in providing economical ultra-rapid charging solutions. Since partnering over two years ago, Rolec and Sinexcel have achieved remarkable success with the installation of UltraCharge 160 units for several high-profile clients, including Porsche, Rolls Royce, Edinburgh City Council, Collins Earthworks, and Yorkshire Ambulance Services. Building on the strength and success of their ongoing partnership, Rolec and Sinexcel are excited to launch the UltraCharge 30, the most compact and affordable 30kW DC rapid charger coming to the market. Purpose-built and designed to meet the evolving needs of businesses, councils, fleets, and destinations. Introducing the UltraCharge 30: a versatile, future-proof EV charging solution, whether wall or pedestal-mounted, the unit offers up to 30kW power output in a space-efficient design. Delivering up to 10-80% charge in under 1.5 hours. With 96% peak efficiency, it optimises energy use, speeding up charging times and maximising ROI. It’s beneficial for sites looking to integrate a robust and rapid EV infrastructure. The UltraCharge 30 features the same trusted controller used in the popular UltraCharge 160, ensuring both reliability and performance. Its competitive pricing makes it an accessible option, minimising upfront costs while providing ease of installation. It combines proven technology with modern advancements to deliver a powerful and cost-effective solution. Compliant with the PAS 1899 accessible charging standard, it’s an ideal solution for destinations where accessibility is essential for serving a diverse customer base. Caravan parks, holiday parks, theme parks, hotels, resorts, shopping centres, sports stadiums, and more should prioritise meeting accessibility regulations. Businesses can offer pay-to-charge solutions and benefit from generating additional revenue. Activation is simple via ISO 15118 plug & charge, mobile app, and RFID, or with the added convenience of an optional contactless payment terminal. Designed with the latest features, it supports dynamic power management, over-the-air updates, an 8” HD user interface touch screen with advertising capability, and is compatible with any OCPP 1.6 CPMS, which is upgradable to OCPP 2.0.1. The UltraCharge 30 features a CCS2 charging connector for fast and reliable compatibility with a wide range of electric vehicles. For seamless operation and data management, the unit supports both 4G and Ethernet connectivity methods, ensuring consistent communication and control. Businesses can benefit from bespoke branding and colour options, whether it’s adding a logo or creating a fully custom design. Businesses who want to provide public EV charging have the option to fully fund the purchase and installation of 30kW DC units through Rolec’s strategic partnership with funding provider, Wattif. This allows businesses to benefit from implementing the latest EV infrastructure without capital expenditure or investment risk. The unit is available for preorder now, with deliveries available from early November.Speaking on the product, Frankie Mellon, Rolec’s Managing Director, said:“I am thrilled to introduce the UltraCharge 30, a major step forward in delivering compact, cost-effective DC charging solutions. This unit is designed to supply rapid charging at an accessible price, with a focus on accessibility for all users. The UltraCharge 30 builds on the success of its big brother, the UltraCharge 160, offering the same tried-and-tested technology in a smaller, very affordable package. We’ve worked closely with Sinexcel to ensure this product is equipped to meet the many requirements of the UK market, such as contactless payment and PAS 1899 accessible charging standard compliance. It also supports ISO 15118 plug & charge for seamless convenience and is future-proof with OCPP 2.0.1 upgradability. The UltraCharge 30 is easy to install and maintain, with full support provided by both Rolec and Sinexcel’s technical teams. As workplaces increasingly demand both DC and AC charging solutions for fleets, visitors, and employees, we offer a reliable and affordable product with a short lead time. Stocked in the UK by Rolec, available for next-day delivery to our UK customers starting later this year.” Charles Meng, Head of Charging Solutions at Sinexcel, commented: “We see our ongoing partnership with Rolec as a significant milestone toward achieving our shared vision. As we’ve deepened our relationship, we’ve become more aligned on common goals. Sinexcel admires Rolec’s steadfast commitment to zero emissions. Their team is professional and precise, consistently impressing us with their deep expertise in the EV charging industry and their drive for innovation. Our team’s visits to Boston since forming this partnership have been both engaging and productive, leading to exciting new aspirations. We’re thrilled to launch the UltraCharge 30 together. We take pride in such exceptional products and are confident that the UltraCharge 30 will be well-received in the UK and EU EV charging sectors.” Building, Design & Construction Magazine | The Choice of Industry Professionals